No products in the basket.

How to convert CO2 to bioplastics in the age of global warming

Posted onGlobal warming, caused by greenhouse gas emissions such as carbon dioxide (CO2) which trap heat in the atmosphere and warms the globe, is becoming increasing prevalent with unsustainable human activity and mass production. To tackle this, we need to begin looking to bioplastics to transition away from traditional petroleum products polluting our environment.

While some sources of emissions causing global warming are natural, (e.g., volcanoes), the rate and intensity of natural emissions are not enough to cause the drastic temperature change observed in past decades. Nature is not contributing significantly to global warming; we are.

Citizens across 19 countries rank global warming as the greatest threat facing their country in the upcoming year. Explaining the increase in average global temperature, global warming is bringing hotter days and more severe hurricanes, wildfires, and other natural disasters.

Widespread deforestation, unsustainable agricultural practices, and the immense release of fossil fuels cause anthropogenic global warming. While burning fossil fuels generates the energy required to power our electricity, it also emits greenhouse gasses – mainly CO2 – that totalled 5,891 million metric tons in 2020.

The plastic production industry

One industry powered by fossil fuels is the plastic production industry. We would produce 56 gigatons, or roughly 13% of total carbon emissions, by 2050 at the current plastic production and consumption rate. Plastic contributes to global warming by emitting greenhouse gasses at every stage of its lifecycle.

From its humble beginning as fossil fuel, plastic is extracted from the earth using energy generated by burning fossil fuel. It is then transported to refining sites and refined through energy obtained by burning fossil fuels. Plastics are distributed to consumers and eventually moved to landfills or recycling centers using fossil fuels. Plastic production and consumption drive the emission of greenhouse gasses, causing more intense climate change and impacting millions of lives.

It’s not difficult to see why. Petroleum-based plastics – everyday plastics – are durable, thermoresistant, waterproof, moldable, and inexpensive, allowing them to be industrialized for single-use packaging. As a result, plastics are mass-produced, consumed, and immediately disposed of, contributing to 79% of waste accumulated in landfills in 2015 and the emission of 850 million metric tons of greenhouse gasses in 2019.

Produce biodegradable plastics using renewable resources

To address the global impact of plastic pollution and greenhouse gas emissions, the Bose lab uses an interdisciplinary approach to produce biodegradable plastics, or bioplastics, using renewable resources, creating a zero-carbon footprint.

Polyhydroxybutyrate (PHB) belongs to a class of polymers (PHA) with similar properties to petroleum plastics, making it a suitable candidate for bioplastics.

Unlike petroleum plastic, PHB is naturally produced as intracellular carbon for energy storage in many microorganisms. Since these organisms can also degrade PHB, PHB-based bioplastics may last only several weeks in landfills instead of petroleum plastics, which last hundreds to thousands of years. While PHB is a promising alternative to conventional plastics, its high production cost and low-efficiency yield make it too expensive for everyday consumers.

Genetic engineering can fix these shortcomings, which seeks to insert PHB genes into model organisms such as Escherichia coli and Saccharomyces cerevisiae to produce PHB. Model organisms are typically favored – numerous genetic tools are available for integrating genes, allowing easy manipulation.

However, these model organisms use organic carbon substrates to make bioplastics, contributing to high bioproduction costs and CO2 emissions. Thus, to achieve the mission of a zero carbon footprint and cheaper input cost, we would need to completely alter model organisms’ metabolism so they could fix CO2ce – or discover new bugs that can already use CO2.

Old bugs & new tools for bioproduction

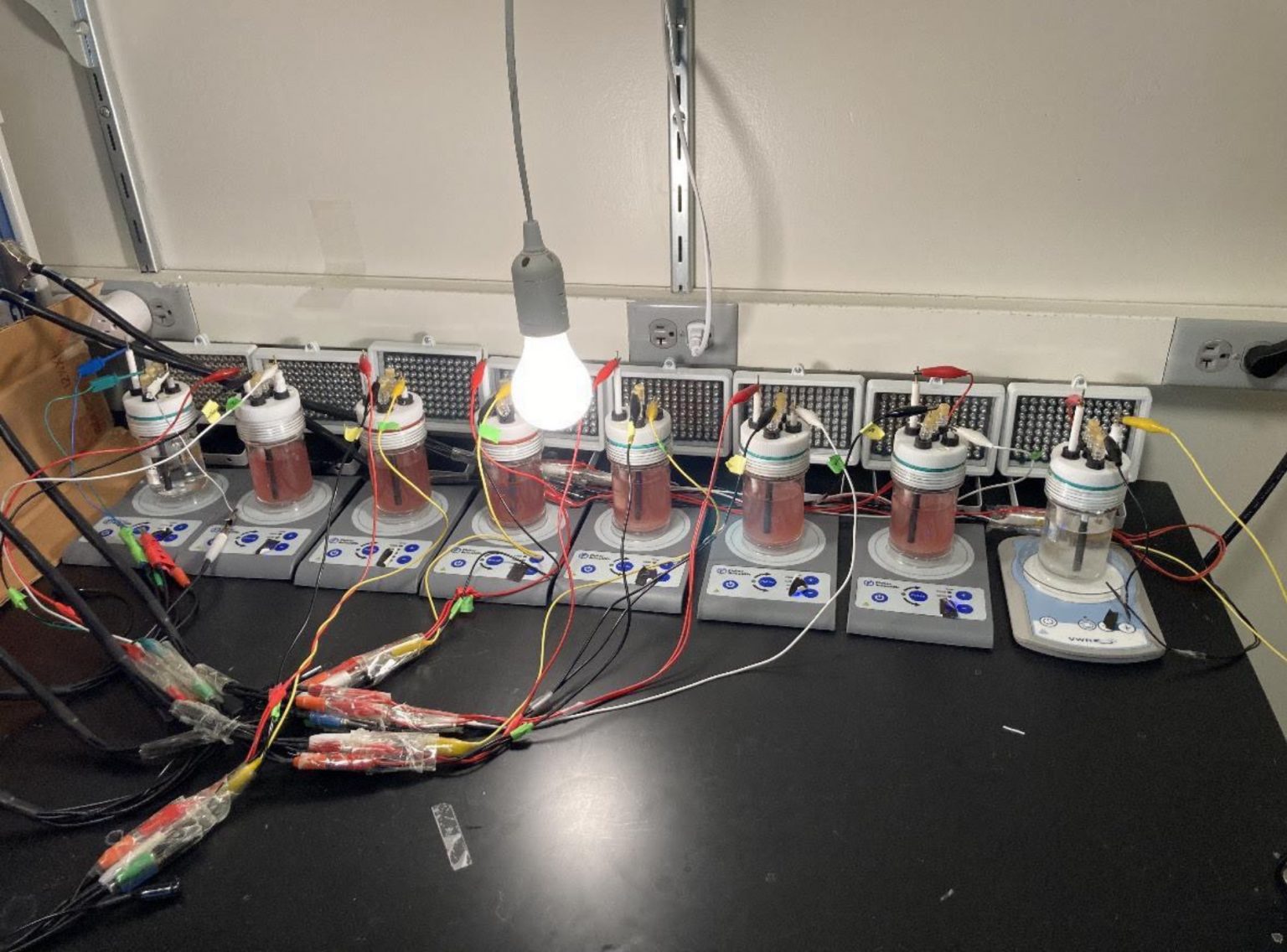

At the Bose Lab, researchers are conducting their experiments on the bacterium Rhodopseudomonas palustris (TIE-1), which has four primary metabolisms that center around fixing either organic or inorganic carbon sources to produce PHB during photosynthesis.

TIE-1 can thrive in Microbial Electrosynthesis, a system that supplies electrons via electric current to microorganisms. This paints a picture of TIE-1 fixing CO2e in solar-panel- powered MES to produce PHB, thus producing bioplastics without the need for expensive carbon and electron sources.

While there’s a relative lack of genetic tools available for TIE-1, researchers were able to increase the production of PHB from TIE-1 by up to 5-fold through the over-expression of RuBisCO, an enzyme responsible for CO2 fixation during the Calvin-Benson-Bassham (CBB) cycle that is active during photosynthesis.

While the highest overproduction (5-fold) is mainly observed when mutant TIE-1 is grown in photoheterotrophic conditions with an organic carbon source, mutant TIE-1 still produces 2-fold more PHB than wild-type TIE-1 when fixing CO2. As more genetic tools are developed for TIE-1, researchers can better manipulate its genome to yield more efficient bioproducts.

New bugs & old tools

Besides promising preliminary research with TIE-1, researchers at the Bose lab are investigating distant relatives of TIE-1: Rhodomicrobium vannielii and Rhodomicrobium udaipurense. Like TIE-1, these bugs are versatile in their metabolism and can produce PHB, making them a suitable candidate for bioproduction.

However, Rhodomicrobium appears to convert electrons to PHB more efficiently than TIE-1 when grown in the same conditions, thus potentially reducing input costs. However, minimal genetic tools exist for Rhodomicrobium, with the most recent technique described in 2023.

While a lack of tools makes studying these bugs harder, it also means these organisms have a lot of potential once genetic tools are developed. Rhodomicrobium’s superior electron yield to TIE-1 shows that it’s crucial to investigate non-model organisms, for they could be a cheaper and a more reliable replacement to model organisms when producing certain bioproducts like bioplastics.

Tiếng Việt

Tiếng Việt